Add:No.831 Jiefang Road,Diankou Area,Zhuji City,Zhejiang,China

Tel: +86 575 87068612

Fax: +86 575 87066789

mail:qiai@qiaigroup.com

Wechat:13967561188

WhatsApp:+86 13967561188

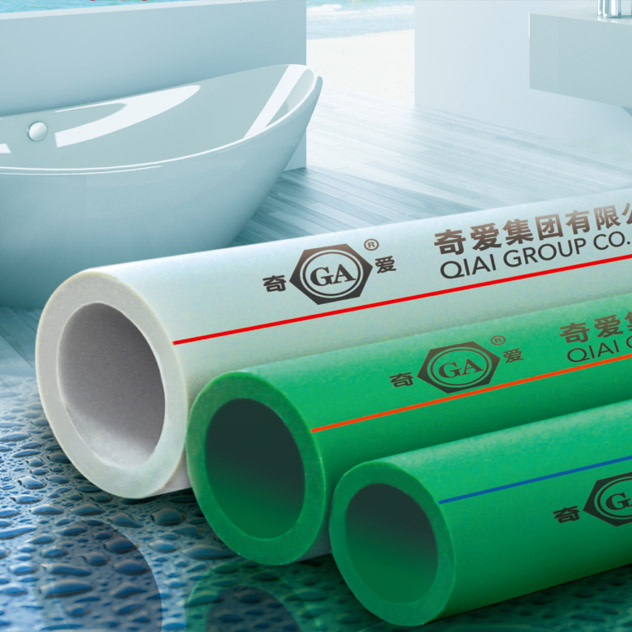

1. Appearance: The color of the surface of the pipe should be uniform and there should be no obvious color difference. The inner and outer surfaces of the pipe should be smooth and flat, and there should be no dents, bubbles, impurities and other surface defects that affect the performance of the product. The end face of the pipe should be cut flat and perpendicular to the axis.

2. The opacity of ppr pipe fittings. The ppr pipe fittings should be opaque.

3. Length: The specified pipe length is 4m, no negative deviation is allowed

The pipe diameter and wall thickness of ppr pipe fittings. According to the GB/T18742.2-2002 standard, the ppr pipe fittings are divided into five series: S5, S4, S3.2, S2.5, and S2 according to the size. The ppr pipe fittings series S has a corresponding relationship with the nominal pressure. The ppr pipe fittings and pipe specifications are represented by the pipe series S, the nominal outer diameter dn * the nominal wall thickness en, and the ppr pipe fittings are mainly inspected for the nominal outer diameter, average outer diameter and The corresponding wall thickness of the pipe series, the socket size of the pipe fittings and the corresponding nominal outer diameter.

4. Hydrostatic strength test: the tested ppr pipe is required to be tested at 20℃, 1h, hydrostatic stress of 16.0Mpa, no rupture and no leakage; 95℃, 22h, hydrostatic stress of 4.3Mpa, no rupture and no leakage; 95℃ , 165h, hydrostatic stress 3.8Mpa, no rupture, no leakage; 95℃, 1000h, hydrostatic stress 3.5Mpa, no rupture, no leakage; 95℃, 1000h, test pressure 0.88Mpa, no rupture, no leakage ;

ZHEJIANG QIAI TUBING INDUSTRY CO.,LTD was established in 1996, is professional China Aluminum Pipe Fittings Manufacturers and Aluminum Pipe Fittings suppliers. QIAI Based on excellent management,relying on the perfect quality system .All the productions passed by ISO9001 international quality management systerm,Certificated by CE.Our main products include: PP-R pipes and fittings,Aluminum pipes and fittings, PE-RT pipes and fittings,Brass Fittings,Water and Gas Valves, Stainless Steel Corrugated Flexible Gas hose, wholesale Aluminum Pipe Fittings, and so on.At present, the company's product sales network has spread all over the world, establish and improve the quality, efficient and fast professional marketing management team and service support system for the vast number of users, welcome!